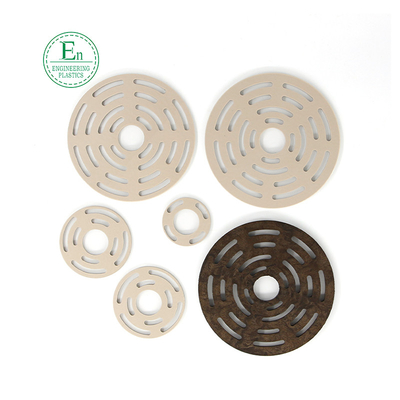

High Quality PEEK Valve

PEEK Material-Model No.:

PEEK-1000 (Natural)

This general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK

grades. The newly available black PEEK 1000 is ideal for instrument components where aesthetics are import-

ant, as well as for seal components where ductility and inertness are important.

PEEK GF30 (30% Glass-Reinforced)

The addition of glass fibers significantly reduces the expansion rate and increases the flexural modulus of

PEEK. This grade is ideal for structural applications that require improved strength, stiffness or stability.

especially at temperatures above 300°F (150°C).

PEEK CA30 (30% Carbon Fiber- Reinforced)

The adition of carbon fibers enhances the compressive strength and stiffness of PEEK, and dramatically

lowers its expansion rate. It offers designers optimum wear resistance and load carrying capability in a

PEEK-based product. Guangzhou Engineering Plastics Industries (Group) Company has studlied and applied

this material in many industries for many years. This grade provides more thermal conductivity than unrein-

forced PEEK -- increasing heat dissipation from bearing surfaces improving bearing life and eapability.

PEEK HPV (Bearing Grade)

Carbon fiber reinforced with graphite and PTFE lubricants, our newest grade of PEEK offers the lowest coeffi-

cient of friction and the best machinability for all PEEK grades. An excellent combination of low friction, low

wear, high LPV, low mating part wear and easy machining, make it ideal for aggressive service bearings.

| Property |

Item No. |

Unit |

PEEK-1000 |

PEEK-CA30 |

PEEK-GF30 |

| 1 |

Density |

g/cm3 |

131 |

1.41 |

1.51 |

| 2 |

Water absorption(23C in air) |

% |

0.20 |

0.14 |

0.14 |

| 3 |

Tensile strength |

MPa |

110 |

130 |

90 |

| 4 |

Tensile strain at break |

% |

20 |

5 |

5 |

| 5 |

Compressive stress(at 2%nominal strain) |

MPa |

57 |

97 |

81 |

| 6 |

Charpy impact strength (unnotched) |

KJ/m2 |

No break |

35 |

35 |

| 7 |

Charpy impact strength (notched) |

KJ/m2 |

3.5 |

4 |

4 |

| 8 |

Tensile modulus ofelasticity |

MPa |

4400 |

7700 |

6300 |

| 9 |

Ball indentation hardness |

N/mm2 |

230 |

325 |

270 |

| 10 |

Rockwell hardness |

-- |

M105 |

M102 |

M99 |

Application

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system,

the product quality conforms to the eu RoHS standard.

Professional Team

Our company has professional product technical consultation and after-sales service. Good

market reputation (quality assurance, reasonable price, timely delivery! ) We will wholeheartedly

provide you with the best quality products, the most thoughtful service!

Guangzhou Engineering Plastics Industries (Group) Co.,Ltd. We have the professional

engineer teams and sales teams, and we have technology and experiences in engineering

plastic industry for morethan 15 years! Our company is located in Huangpu District, Guang

zhou City, China, where the logistics is developed! With the rich experiences and technology

for manufacture, design, research and development ability, support personalized

customization. We have full set of high efficiency producing equipment and advanced

numerical control machines,such as: molding injection machines, CNC molding manufacture

machines, fine carving machines, Horizontal lathes, milling machines. We can customize all

kinds ofEngineering plastics products according to our customers’drawings or samples.

Our Factory

Specializing in the production of "engineering plastic accessories" of high-tech enterprises,

the company has a set of imported production equipment and CNC processing equipment,

processing means advanced, strong technical force.

Exhibition & Our Strength

Our company has rich experience, strong strength and participated in many high-level

exhibitions. Many partners from other countries are visiting.

Cooperation

Cooperate with many well-known companies.

Buying Instructions

Q1. We dun'l have drawings, can we produce accurding Lu the sarnples we

provide?

A1. OK

Q2. How to customizc plastic parts?

A2. Cl1stomized according to drawings

Q3. Can I make a sample for tnsting first?

A3. OK

Q4. How long is the prooting cycle'?

A4.2-5 days .

Q5. What are your processing eqipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine,

injection molding machine, extruder, molding machine.

Q6. What craftsmanship do you have for processing accessories?

A6 .According to different products, different processes are used, such as

machining, extrusion, injection molding, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!